LENCO TECHNICAL NEWSLETTER #1

![]() is not only the supplier of Royal Purple high quality lubricants but also it should be considered as a technical resource for the operations of your equipment.

is not only the supplier of Royal Purple high quality lubricants but also it should be considered as a technical resource for the operations of your equipment.

Millions of bearings are operating everyday but very few of these would reach their expected end life for many different reasons.

Below are the most significant reasons:

• Improper installation or poor machine design

• Entry of external contaminant such as water and dirt

• Wear and Fatigue

Rolling Element Bearings are bearings with rolling elements in them (balls, rollers or cones) turning between 2 races. There are varieties of Rolling Element Bearings in the market. The most known are: Deep Groove Ball Bearings, Roller Bearings, Spherical Roller Bearings, Thrust Roller Bearings and Needle Bearings.

Wear occurs when the oil film between the rolling elements and the race is insufficient.

This results in metal contact with the main effect leading to a reduction in the life of the bearing.

The thickness of the oil film is mainly dependent on the circumferential speed of the bearing and the viscosity of the oil operating temperature.

You must keep in mind that when the temperature increases, the viscosity of the oil decreases.

The oil film thickness must be at least equal to 2 times the roughness of the metal surface.

Typical roughness for rolling element bearings is less than 0.5 microns (0.02 milli inch)

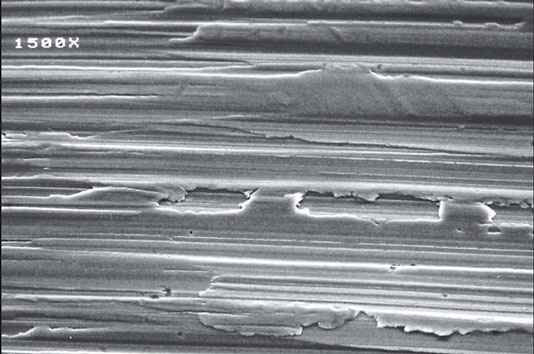

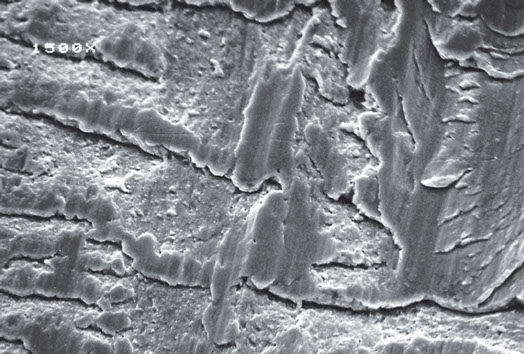

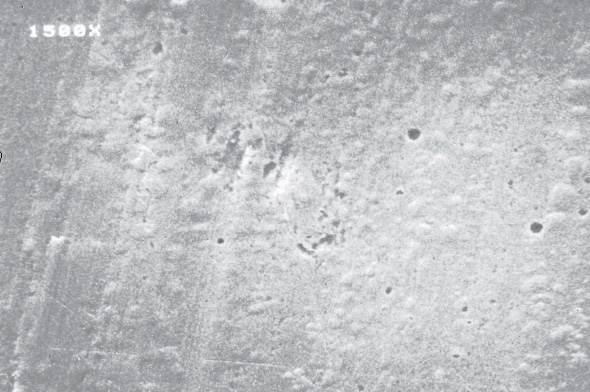

Microscopic Photos of Micro-Polishing

New mechanical bearing surface appears

smooth until magnified 1,500 times.

Same bearing surface galled using a premium, competitive synthetic oil (1,500 power).

Same bearing surface after being micro-polished by

Royal Purple’s proprietary Synerlec® additive technology

(1,500 power).

Fatigue is not only a result of contact between races and rolling elements. In the load zone of the bearing, immense pressure, called Hertzian Pressure, is generated at the interface between the rolling element and the race. In this area the lubricant becomes pseudo-solid (similar to a glass film) and the metal deforms. This high pressure propagates inside the metal. Once the rolling element leaves the load zone, the metal surfaces from the rolling element and the race recover their original shape and the oil becomes fluid again. This type of lubrication is called Elasto-Hydrodynamic Lubrication, or EHL for short. The repetitive passage of rolling elements in the load zone will ultimately create subsurface cracks. To slow down the fatigue process, a heavy viscosity oil can help by increasing the width of the interface between the rolling element and the race.

The additives present in the oil can reduce the roughness of the metal surface and decrease wear and fatigue. The presence of acidic additives and water in the oil increase the rate of propagation of the cracks in the metal by corroding the metal and weakening the bonds between atoms.

To reduce wear and fatigue of rolling bearings, operators of machines should consider using a high quality lubricant with the following features:

- A viscosity at operating temperature thick enough to create an oil film 3 to 4 times the surface roughness of the metal

- Anti-wear additives enabling a micro polishing of the metal surface in the load zone

- An effective separation of water and and oil (Demulsibility)

LENCO markets Royal Purple High Performance Synthetic oils and greases. Compared to mineral oils, synthetic lubricants do not change of viscosity as much with a change of temperature.

At operating temperature, the oil film generated by a synthetic oil will likely be a lot thicker than a mineral oil. But at an initial phase, the synthetic oil is still fluid enough to provide an immediate protection of the moving parts.

Royal Purple oils, for example Synergy gear oil and Synfilm™ circulation oil and Ultra Performance grease, contain outstanding anti-wear additives like: Synslide™ and Synerlec™. Those additives score very high marks in international wear protection tests. Synslide™ and Synerlec™ are noncorrosive at the difference of most Extreme Pressure additives.

Royal Purple lubricants have the capability of separating from water very rapidly and completely.

LENCO stocks Synergy and Synfilm™ lubricants in a wide range of viscosity in Jebel Ali Free Zone, Dubai from ISO VG 32 to ISO VG 460 and can import lubricant up to a viscosity ISO VG 1500.

LENCO technical support is able to confirm the optimum viscosity required for the lubrication of the rolling element bearings operating in your plant.

Just contact LENCO with your questions and our Lubrication Engineers and Staff will be pleased to assist you with any technical support you may require.

Limited Liability Company.

Share Capital: AED 400,000.

Decree No. (6) of 1995 as amended by Sharjah Executive Council resolution no.(1) of 2000.

© 2008 - 2015 LENCO Middle East FZC

Trade License Number: 4194.

Formation under SharjahEmiri